Introduction: Why Care About the Price of LED Panels?

From advertisements in shopping malls to stage screens, you LED panels They have become essential elements in modern communication. But when it comes time to buy, you realize: screens of the same size can cost up to 3 times more! A panel P1.0 (1mm) exceeds R15000/㎡, while the P10 Basic costs only R2000/m² – factors such as pitch (spacing between pixels), brightness and IP protection directly impact the cost.

The worst part? The market is full of traps: false specifications, refurbished products sold as new, and limited warranties can all increase your expenses. Choosing the wrong model (such as using an outdoor panel indoors) can increase your budget by up to 40%.

In this 2025 guide, you will:

- Compare real prices from P1 to P10 (updated for the Brazilian market)

- Understand why outdoor panels cost twice as much (IP65 vs IP20 protection)

- Avoid 5 common mistakes and save up to 30% on your project

Whether buying or renting, mastering pricing logic prevents losses!

Interpreting the main parameters helps to understand the main factors that affect the price of the LED panel: How to understand the technical parameters table?

When buying an LED screen, the table of technical parameters provided by the manufacturer can be surprising:“P2.5“, “3840 Hz refresh rate”, “SMD packaging“… What do these professional terms mean? In fact, you only need to pay attention to the following 4 main parameters to quickly determine the applicable scenarios and the cost structure of the screen.

Parameter 1: Pixel pitch – the main indicator that determines clarity

What is pixel pitch?

Refers to the center distance between two adjacent LED beads (unit: mm). For example, in P2.5, the pixel pitch is 2.5 mm.

The smaller the value → the greater the pixel density The image will be sharper, but the price will also increase.

Buying Guide:

| Pixel Pitch | Optimal viewing distance | Typical uses | Price sensitivity |

| P1.0-P1.8 | 0.5-3 meters | Virtual filming/high-level conference | ★★★★★ |

| P2.0-P2.5 | 3-6 meters | Corporate exhibition hall/monitoring center | ★★★★☆ |

| P3.0-P4.0 | 6-10 meters | Retail/Conference Room Advertising | ★★★☆☆ |

| P5.0-P10.0 | 10-30 meters | Outdoor large screen/sports stadium | ★★☆☆☆ |

Its formula: Minimum viewing distance (meters) ≈ pixel pitch (mm) × 2

(Example: A P2.5 screen requires at least 5 meters of viewing distance)

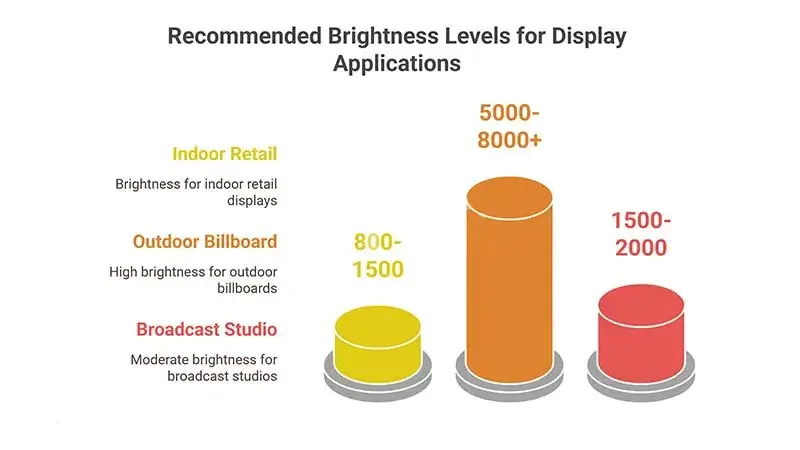

Parameter 2: Brightness – Survivability under ambient light

Why is it important?

If the brightness of the internal screen is insufficient, it will be “invisible” in the sun, and if the brightness of the external screen is too high, it will glare and consume energy.

Reference standard:

| Scene | Recommended brightness (nit) | Special requirements |

| Inner dark light | 800-1,500 | Low blue light eye protection |

| Bright internal light | 1,500-2,500 | Anti-reflective coating |

| Semi-external | 2,500-5,000 | IP54 dust and water resistance |

| Direct outdoor sunlight | 5,000-10,000 | IP65/IP68 + automatic brightness adjustment |

Note: Some low-cost displays on the market are labeled "ultra-high brightness," but this is achieved by sacrificing color uniformity. You can ask the manufacturer for a brightness measurement report!

Parameter 3: Core Technology Disassembly: How does LED packaging process affect price and service life?

When you find products packaged with terms like “SMD, COB, "GOB," what you really need to pay attention to is how packaging technology affects the three main screen experiences:

- Image quality performance (color uniformity/contrast)

- Reliability (anti-collision/waterproof/heat dissipation)

- Total cost of ownership (maintenance difficulty/life cycle)

Comparison of the three main current packaging technologies

| Type | Schematic diagram | Advantages | Suitable for scenarios | Price coefficient |

| SMD | [SMD] LED beads packaged separately | Mature and stable/bright colors | Internal fixed installation | 1.0x |

| COB | [COB] Directly packaged chip | Seamless/Anti-collision/Good heat dissipation | High-end commercial stage/exhibition rental | 1.5-2.0x |

| GOB | [GOB] Colloidal protection | Waterproof and dustproof / strong pressure resistance | Outdoor/industrial environment | 1.2-1.8x |

Note: The price coefficient is based on P2.5 SMD screen (such as COB with the same specification is 50%-100% more expensive)

Purchasing traps caused by technical details

Pitfall 1: Confusing “surface mount” with “normal mount”

With the same “SMD” label, the normal mount LED (with the lamp beads facing forward) is 30% brighter than the side mount LED (with the lamp beads tilted), but some manufacturers mix them for profit.

Pitfall 2: “Full COB flip-chip” fake.

True flip-chip COB must use Flip-Chip chips, while low-end products use normal assembly chips + camouflage technology, and the heat dissipation performance is 3 times worse.

Pitfall 3: GOB Glue Cuts Costs.

High-quality polyurethane glue can withstand temperature differences from -40°C to 85°C, while inferior epoxy resin glue will yellow and crack after 1 year.

Your decision list

- Choose SMD if: limited budget + need for vibrant colors (like shopping mall ads)

- Choose COB if: frequent handling + need for ultra-thin and seamless (like concert screens)

- Choose GOB if: high humidity/dust + long-term maintenance-free (like gas station screens)

Important inspection tips:

- Scratch the surface of the COB screen with your fingernails – the actual COB should not have a grainy texture

- Shine a bright flashlight obliquely onto the GOB screen – the colloid should not have bubbles or cracks.

Why is this important?

A customer once chose the wrong packaging type, which caused a large area of a $150,000 outdoor screen to short-circuit after a heavy rainstorm—packaging technology directly determines the screen's lifespan!

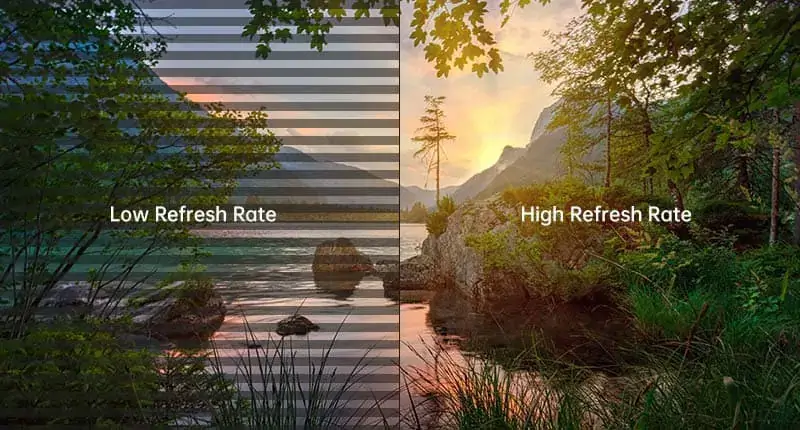

Refresh Rate In-Depth Analysis: Can Your Screen “Blind” You?

Why do some LED screens with the same resolution cause eye pain after long viewing, while others are extremely smooth?

3840Hz → professional stage screen (no flicker to the naked eye, no blur in high-speed photography)

1920Hz → common screen for conference room/advertising (comfortable for human eyes)

<960Hz → low-cost screen (some people may experience flickering, and prolonged viewing will cause fatigue)

In dynamic scenes, how does refresh rate affect the user experience?

| Scene requirements | Minimum refresh rate requirement | Reasons |

| Static graphical display | ≥960Hz | Basically flicker free |

| Video playback | ≥1920Hz | Avoids motion blur |

| Live sporting events | ≥3840Hz | Captures high-speed motion |

| XR virtual filming | ≥7680Hz | Matches the camera frame rate |

Note: Some low-end displays will automatically reduce the refresh rate in low brightness mode (e.g. from 1920Hz to 480Hz), resulting in visible flickering!

Price Impact: Why Are High Refresh Rate Screens So Expensive?

| Refresh rate gear | Increased costs | Applicable scenarios |

| 960Hz → 1920Hz | +15% | Conference room/retail advertising |

| 1920Hz → 3840Hz+ | +30% | Sports stage/stadium |

| 3840Hz → 7680Hz | +80% | Virtual photography/high-speed photography |

Purchase suggestions:

- Conference roomShowroom: 1920 Hz (best value for money)

- Stage/show: ≥3840 Hz (prevents blur under high-speed lenses)

- Don't pay for an ultra-high refresh rate you don't need!

The latest reference table of LED panel price

| Pixel Pitch | LED Panel Value Internal (usd/㎡) | LED Panel Value External (usd/㎡) | Premium Ratio | Typical Applications |

| P1.0 | 1800-2700 | 3600-7000 | +100%-147% | Film and television filming, high-end commercial showrooms |

| P1.5 | 1300-1700 | 3000-4800 | +125%-180% | Corporate exhibition rooms, monitoring centers |

| P2.5 | 850-1200 | 1800-3200 | +111%-167% | Conference rooms, retail advertising |

| P3.91 | 800-1000 | 1600-2800 | +98%-174% | Stage backdrops, digital signage |

| P5.0 | 600-800 | 1100-2000 | +81%-150% | Shopping mall screens, traffic information screens |

| P10.0 | 400-500 | 800-1300 | +94%-160% | Billboards, sports stadiums |

Note: Price fluctuation factors (brand, batch, after-sales policy, etc.)

Indoor vs. Outdoor LED Displays: Why the Price Difference Is 2 to 3 Times Bigger? Key Differences Revealed

When you find that the outdoor version of the LED screen with the same P2.5 pitch is 200% to 300% more expensive than the indoor version, you are basically buying these invisible technical configurations:

The “survival gear” of outdoor screens vs. the “greenhouse privilege” of indoor screens

| Dimension comparison | Mandatory configuration for external displays | Simple internal screen setup | Cost impact |

| Waterproof and dustproof | IP65 grade (no water ingress when washing with high pressure water gun) | No protection (exposed circuit board) | +25% |

| Shine | 8000-10000nits (Direct sunlight resistant) | 800-1500nits (depending on ambient light) | +40% |

| Cooling system | Aluminum heat sink + fan (-30°C to 60°C operation) | Natural heat dissipation (15°C~35°C) | +30% |

| Structural reinforcement | Steel frame + windproof anchor point (12-level typhoon resistant) | Common sheet metal enclosure | +20% |

| Corrosion resistance | Gold-plated interface + triple paint (anti-salt spray/acid rain) | Common copper | +15% |

Which display screen should you buy? 4 thought-provoking questions

1. Will it be exposed to rain and snow?

If it's likely to get wet, choose an outdoor screen (IP65). The cost of modifying the "waterproof kit" of an indoor screen is higher than purchasing an outdoor screen outright.

2. How long does the screen last per day?

8 hours/day → an outdoor screen is required (continuous operation at high brightness of the indoor screen will accelerate aging).

3. Is the ambient temperature extreme?

Winter in the Northeast/-20°C → the heating function of the outdoor screen is required

(Common screens may not work below -10°C).

4. Does it need to be moved?

Rental/Temporary Installation Screen → Choose a lightweight outdoor screen (≤35kg/㎡)

(Traditional outdoor screens weigh 50kg/㎡ and the lifting rate is doubled.)

Ultimate solution for cost savings

- Semi-outdoor scenarios (such as station awnings/umbrellas):

Choose inner screen + GOB packaging + outer rain cover, the cost is 40% lower than outer screen. - Short-term activities (<3 months):

Rent a waterproof screen (with quick release frame), saving 60% compared to purchasing an outdoor screen.

How to reduce the cost of purchasing LED screens?

——3 Strategies + 5 Practical Skills, Save 40% from Budget

When the client says "cut the budget in half," cost optimization doesn't mean cutting costs, but rather precisely meeting real needs. Here's a proven cost-cutting methodology:

Strategy 1: Select on demand – no need to blindly chase “small pitches”

Case of mistake

A company purchased a P1.8 screen (total price 480,000) for its conference room. The actual viewing distance is 6 meters and the pixel density is extremely excessive.

Optimization plan: Replace with a P2.5 screen (no difference in effect, saving 230,000).

Golden formula for selection

Most economical spacing = shortest viewing distance (meters) ÷ 8

(Applicable to graphic/video scenes, XR virtual shooting requires ÷ 4)

| Scene | Pixel Pitch | Saves over P1.8 |

| Meeting room (4-6 meters) | P2.5~P3 | 40%~60% |

| Shopping mall atrium (8 meters) | P4~P6 | 70%+ |

| Outdoor advertising (10 meters) | P8~P10 | 85%+ |

Hidden benefits: Large-pitch screens have better heat dissipation, and their service life is generally 30% longer than that of small-pitch screens.

Strategy 2: Supply chain optimization – avoid “interception” by intermediaries

LED display factories are concentrated in Shenzhen, China. The LED display industry is concentrated here, even being located in an industrial park. All the accessories needed for LED display production are available here. This fully reflects the advantage of cost control.

If you want the best price, buying from direct factories in China is obviously the best option. Typically, this can save you about 20% in expenses.

Additionally, planning your purchases in advance will benefit your shipping arrangements. You can use containerized shipping (especially for large screens above P6), which can save 60% in logistics costs.

Strategy 3: Hybrid solution – flexible satisfaction of rigid demands

“Dimension reduction solution” for semi-outdoor scenarios

| Demand | Cost of full outdoor screen (IP68) | Alternative solutions | Savings |

| Awning/Under the eaves | 100% | Internal screen + GOB packaging | 35% |

| Temporary activities | 100% | Waterproof canvas for rental (recyclable) | 60% |

Based on a 3-year usage cycle, the total cost of leasing is 54% less than purchasing

Advanced Skills: Hidden Bargaining Chips on the Trading Table

1. Credit conditions for exchange for discounts:

Cash payment → 20% discount

Semi-annual acceptance account → 15% discount (manufacturer's cost of capital is about 12% per year)

2. Off-season shopping (March-April/September-October):

The display industry exhibits clear seasonality, and the negotiation space for off-season orders increases from 8% to 15%.

3. “Binding” consumables package:

Promise the manufacturer to provide maintenance consumables for the next 5 years, which can reduce the hardware budget by 10% to 20%.

Pitfalls in buying LED screens and a guide to avoid them

——From false parameters to reduced after-sales service, a comprehensive analysis of the industry’s pitfalls and countermeasures

You think you've purchased a "budget" LED screen, but it may actually be a refurbished product with false parameters and no after-sales service. This section uses real measurement data and unwritten industry rules to help you accurately avoid these pitfalls.

Pit 1: False parameters (brightness/refresh rate/color gamut)

How to inspect the products?

1. Brightness (Nits)

- Industry jargon: “Maximum brightness” ≠ “continuous brightness” (some manufacturers claim 8000 nits, but in reality only 2000 nits can be maintained stably)

Breaking method: - A third party test report is required.

- Test with an illuminance meter for 1 hour on site.

2. Refresh rate (Hz).

- The pseudo “3840Hz” may be an interpolation algorithm, and the actual refresh rate may be only 1920Hz.

Breaking method: - Shoot in slow motion (240 fps+) with your phone to see if there is any flickering or scanning lines.

3. Color gamut (sRGB/Adobe RGB).

- Low-cost displays use “software enhancement” to pretend to have a wide color gamut.

Breaking method: - Require a demonstration of a pure color (red/green/blue) test screen and measure with a colorimeter. (such as X-Rite i1)

Pitfall 2: Refurbishing used screens (how to identify a new screen?)

Common characteristics of refurbished screens

- Screw removal marks (original screws have anti-disassembly marks)

- Inconsistent module serial numbers (regular lot numbers of new screens are continuous)

- LED lamp color temperature difference (refurbished screens are mixed with old modules)

Inspection Tips

1, Ultraviolet irradiation method

- The new screen's printed circuit board has an antioxidant coating, which emits purple light under ultraviolet irradiation, and the refurbished screen does not exhibit this reaction due to aging.

2, Driver IC Detection

- Common teardown ICs for refurbished modules (such as the older Macroblock MBI5124 model)

- Newer displays should use the latest ICs (such as the MBI5359)

Main terms of the contract:

“If refurbished parts are found, compensation of 300% will be made based on the total order value” (to deter suppliers)

Four-step guide to avoiding pitfalls

1. Request an official test report

- Brightness (ANSI lumen test)

- Color gamut (sRGB/Adobe RGB coverage)

- MTBF (>50,000 hours for qualified)

2. Investigate real cases

- Demand projects in the same industry (such as hotels/retail/sports facilities)

- Investigate cases running for more than 1 year (note the dead light rate)

3. Main terms of the contract (must be written in black and white)

- Warranty scope: Please clarify whether the module/power supply/control system is fully covered

- Spare parts support: promise the proportion of spare parts in stock (such as ≥ 5%)

- Maintenance cost: Guarantee the increase in labor costs within 5 years (as ≤ CPI growth rate)

4. Avoid payment method traps

- 30% advance payment + 70% after inspection

- Rejection clause: full refund if parameters are not met

LED panel price trend forecast for the next three years

——Mini LED Volume Growth vs. Chip Sanctions: Will It Increase or Decrease in 2025?

Prerequisite for completion:

“Structural differentiation” in 2024-2025 – small pitch price reduction (below P2.5) from 15% to 20%, increase of LED panel prices high quality external from 8% to 12%

(Key variable: Progress of mass production of driver integrated circuits in China)

The main driving force behind price reductions

1, Mini LED mass production cost drops (tipping point in 2025)

Technological progress curve

| Years | P1.2 Module Cost (USD/㎡) | Main advances |

| 2023 | 2600 | Experimental production of small batches of 4μm chips |

| 2024 | 2200 (↓14%) | Massive transfer throughput increased to 99.98% |

| 2025 | 1800 (↓30%soma) | Sanan/Huacan 6-inch wafer fab put into production |

Market impact:

- P1.5-P2.0 becomes the mainstream choice in conference rooms (penetration rate may exceed 60% by 2025).

- The price of COB packaging is 40% lower than SMD (but the maintenance cost is high and needs to be considered).

Industry forecast: When the cost of P1.0 screen is ≤ USD 1,500/㎡, it will replace 70% in the LCD splicing wall market.

2, Replacement of domestic chips (localization rate may reach 80% in 2024)

Cost comparison (LED chips/thousand)

| Manufacturers | 2023 Prices | Forecast for 2025 | Technological gap |

| Nichia Chemical | 45USD | 43USD | Luminous efficiency is 5% higher, but export is restricted |

| Sanan Optoelectronics | 37USD | 29USD | Reliability reaches automotive level |

| Huacan Optoelectronics | 34USD | 26USD | ESD resistance is slightly weaker |

Replacement bonus:

- P2.5 screen with domestic chips can reduce BOM costs by 18% to 25%.

- Attention: The light decay rate of low-cost domestic chips (such as those from a Fujian manufacturer) is 3 times higher than the industry standard.

Purchasing Strategy Recommendations for 2025

Buy expensive or cheap? Scenario-based decision making

| Demand scenarios | Best time to buy | Alternative solutions |

| P1.2 or lower | After the fourth quarter of 2024 | Wait for the release of Mini LED production capacity |

| External P4-P6 | First half of 2024 | Avoid the Driver IC Sanctions Window Period |

| Screen for rent | Wait and see in the long term | Switch to transparent Micro LED screen (will become affordable in 3 years) |

3 Buffer Solutions to Contain Price Increases

1. Order Lock-in Strategy: Sign a 2-year price agreement in 2024 (like the one offered by Leman Optoelectronics)

2. Future purchases: Reserve 2025 production capacity at current price (20% margin required)

3. Modular design: Purchase 70% of the screens first and reserve the interfaces for subsequent expansion

In one sentence

“When choosing an LED screen, don’t choose the most expensive one, but the most suitable one!”

Quick Reference Chart for Screen Purchasing Decisions

| Demand | Recommended solution | Important points to note |

| Short-term events | P3-P4 rental (including installation and debugging) | The contract stipulates that the refresh rate is ≥ 3840 Hz |

| Corporate meeting rooms | Mixed implementation P1.8+P2.5 | Choose COB screen carefully (high maintenance cost) |

| Outdoor advertising | Direct installation of the IP65 protective screen | Calculate the 10-year TCO, don't limit yourself to the unit price |

Definitive advice

1. Rent for short-term use, buy for long-term use

2. Write down your needs clearly = save over 20% directly

3. By 2025, small screens will fall and high-end outdoor screens will rise – hit the right knot!