The term DIP LED stands for Dual In-Line Package LED. It is one of the types of LED packaging. diode older and more reliable light emitters still used today, especially in LED displays For outdoor use, traffic signage, and large billboards. Although surface mount technology (SMT) has become dominant in recent years, DIP LED modules remain a popular option due to their durability, brightness, and long lifespan.

Let's take a closer look at what makes DIP LED technology unique and why it's still important in modern applications.

What is a DIP LED?

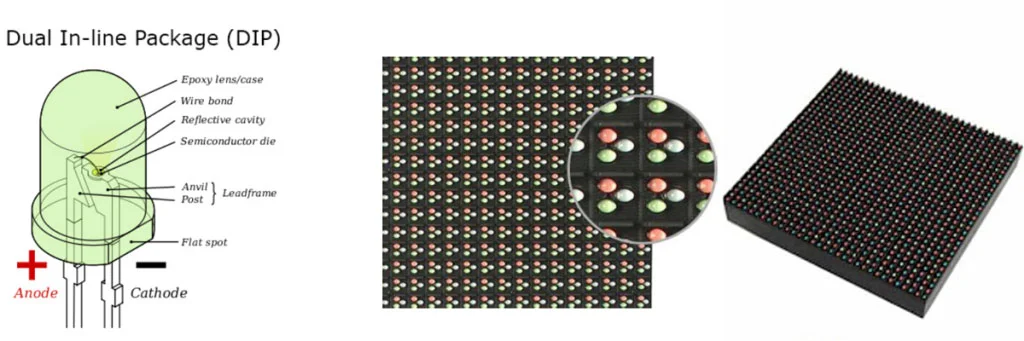

DIP LED packaging is a traditional type of LED packaging where each diode is encased in a rigid epoxy resin and mounted through holes in a printed circuit board (PCB). The name "dual in-line packaging" comes from the two parallel connection pins that extend from the LED body, allowing it to be inserted and soldered onto the board.

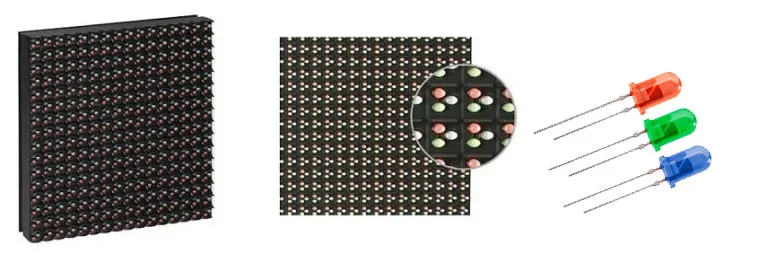

These LEDs are easily recognizable, generally cylindrical in shape, about 3 mm or 5 mm in diameter, and are frequently found in red, green, or blue colors.

Structure and operating principle of the DIP LED

A DIP LED has three main parts:

- Epoxy lens – It protects the LED chip and focuses the light beam.

- LED chip – The semiconductor core that emits light when an electric current passes through it.

- Connection pins – Two metal terminals that connect the LED to the printed circuit board.

Advantages of DIP LED technology

Despite the latest LED types, such as SMD and COB, However, DIP LEDs still have several advantages that make them the ideal choice for certain projects.

High brightness and visibility

Excellent heat dissipation

Because DIP LED modules are individually mounted and spaced apart, they dissipate heat better than compact LED modules. This helps maintain consistent performance and extends lifespan, even at high temperatures.

Long lifespan and durability

Coated with a thick layer of epoxy, DIP LEDs withstand harsh environmental conditions such as rain, dust, vibration, and temperature variations without loss of performance. They can operate reliably for over 100,000 hours.

Energy efficiency

Despite their age, DIP LED designs remain energy efficient. They provide high brightness while consuming minimal energy compared to incandescent or fluorescent lamps.

Stable color and brightness.

Unlike SMD models, which can lose intensity over time, DIP LED modules maintain consistent brightness and color stability, which is vital for large digital displays and electronic scoreboards.

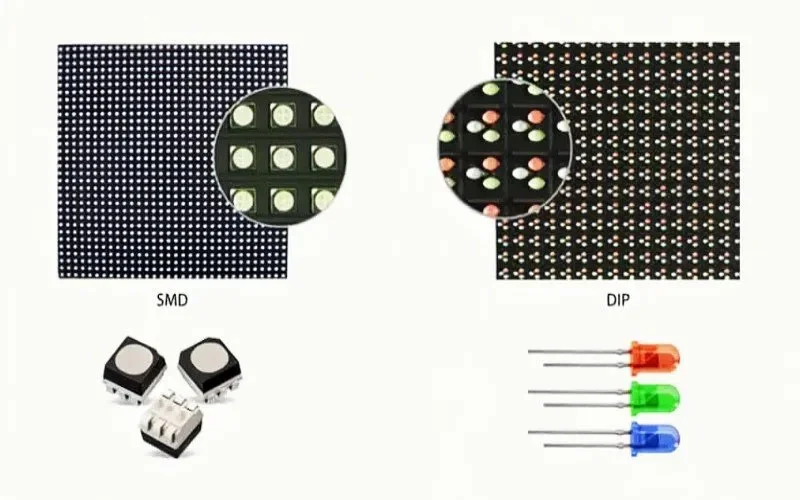

Comparison: DIP LED vs. SMD LED

| Appeal | DIP LED | SMD LED |

| Structure | Two-pin LED with through-hole mounting | Surface mount directly onto the printed circuit board (PCB) |

| Shine | Greater brightness, focused beam | Lower brightness, wider beam |

| Viewing angle | Narrow (usually 60° to 90°) | Wide angle (120° – 160°) |

| Durability | More resistant to weathering | More fragile in adverse conditions. |

| Applications | Outdoor displays, signs and traffic lights | Indoor screens, TVs, mobile devices |

| Maintenance | Easier individual replacement | More durable due to impact design. |

Although SMD LEDs dominate indoor and high-resolution displays due to their small size and versatility, DIP LEDs remain unbeatable for outdoor environments that demand brightness and durability.

What is a DIP LED chip?

A DIP LED chip is simply the LED chip used inside a DIP package. It is the semiconductor component responsible for producing light. Each chip is designed to emit a specific color (red, green, or blue), and multiple chips can be combined into a module to produce full-color (RGB) effects.

For example, an outdoor RGB display, made with DIP LED modules, uses separate red, green, and blue DIP LEDs arranged close together to create vibrant, colorful images.

LED DIP display applications

Due to their brightness and robustness, DIP LEDs are commonly used in:

- Outdoor advertising panels High brightness ensures visibility even in direct sunlight.

- Big screens and stadium scoreboards – Long viewing distance and strong color contrast.

- Signage and information panels Reliable in extreme heat, rain, or cold.

- Industrial equipment Durable enough for use in factories or demanding applications.

The future of DIP LED technology

Although the display industry increasingly uses SMD and COB LEDs for compact, high-resolution applications, DIP LED technology isn't going away. Manufacturers continue to improve its efficiency and weather resistance, making it a reliable option for large outdoor installations.

Modern DIP LED designs with chips are now integrated with advanced driver integrated circuits and energy-saving circuitry, helping to bridge the gap between traditional reliability and modern efficiency.

Final considerations

Although DIP LED technology is older, its reliability keeps it relevant in today's display market. The DIP LED structure, with its robust epoxy housing and high light output, remains essential for outdoor applications where brightness and durability are fundamental. And, as DIP LED technology evolves, it continues to meet the needs of industries that require powerful and long-lasting light sources capable of operating even in the most adverse conditions.