Every LED electronic system, whether it's a billboard, a display panel, or a smart lamp, depends on one crucial component: the LED chip. These microscopic semiconductors convert electrical current into visible light, determining the brightness, efficiency, and reliability of an LED product.

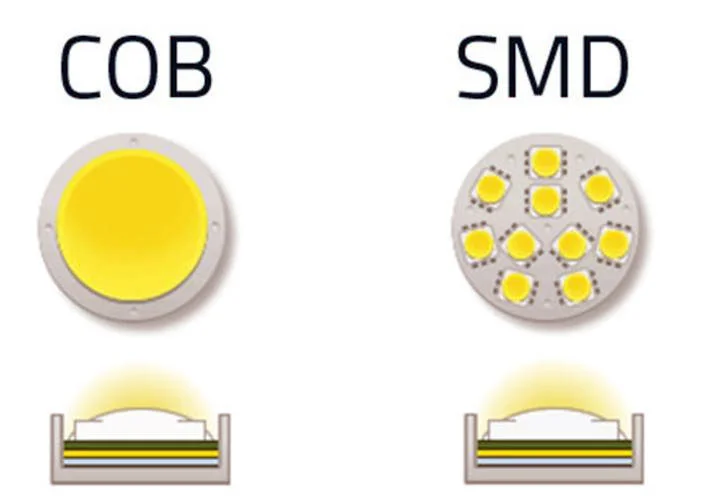

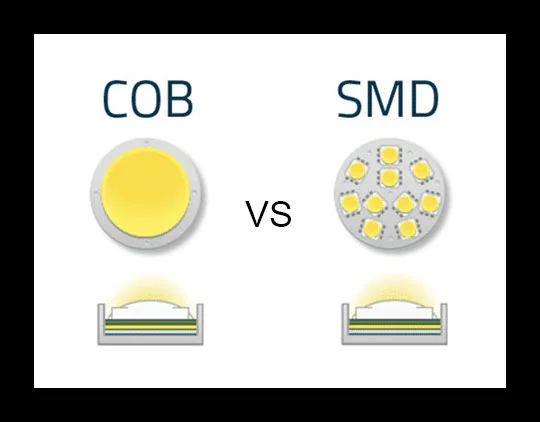

Two leading LED chip technologies, COB (Chips on Board) and SMD (Surface-Mounted Devices) dominate the LED industry. Understanding their structure, performance, and differences helps you choose the right technology for your LED electronics applications, whether for precision lighting or high-definition displays.

What are LED chips in LED electronic systems?

At the heart of every LED electronic circuit is the LED chip; a semiconductor light source that produces illumination through electroluminescence. The chip's efficiency determines how much electrical energy is converted into light instead of heat, influencing energy consumption and lifespan.

LED chips are constructed from compound semiconductors, such as gallium nitride (GaN) and aluminum gallium indium phosphide (AGaInP). When an electrical voltage passes through the chip, electrons recombine with holes in the pn junction, releasing photons. The emitted wavelength defines the LED's color, while phosphor coatings create white light for general illumination.

SMD LED chips: Versatile and robust components for LEDs in electronics.

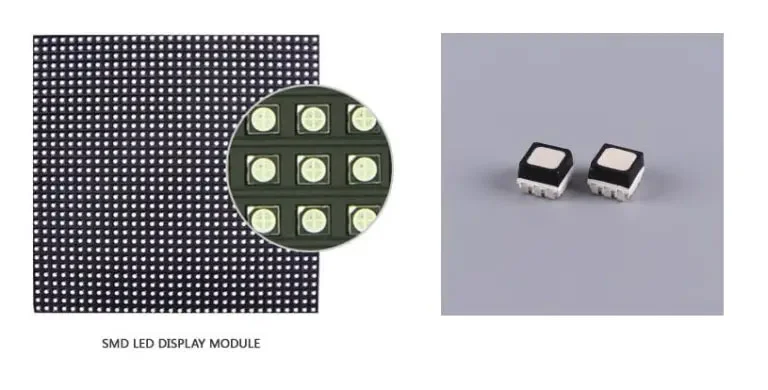

SMD (Surface Mount Device) LED chips are mounted directly onto printed circuit boards (PCBs). They are among the most widely used in LED lighting and electrical signage due to their flexibility, compact design, and luminous efficiency.

The most common types include SMD 2835, 3528, 5050, and 5630, where the numbers correspond to the chip size in millimeters.

Technical characteristics:

- Luminous efficacy: 160-220 lm/W

- Beam angle: 120° – 160°

- Casing: Epoxy resin with gold wire bonding.

- Power: 0.2 – 1.0 W (typical)

Advantages:

- Lightweight and compatible with automated assembly.

- Easy RGB configuration for colorful LED electronic displays.

- Wide lighting coverage

Disadvantages:

- Higher junction temperatures in dense layouts.

- Requires diffusers for uniform light curvature.

Applications:

- LED strips and tubes

- Pixel-based LED screens and scoreboards

- LED electronic signage for indoor environments and commercial lighting.

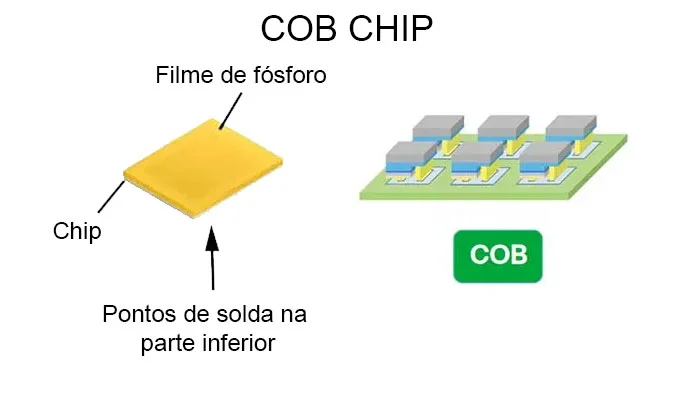

COB LED Chips: Compact Powder for LEDs

COB (Chips on Board) technology integrates multiple LED chips onto a single substrate, forming a dense light-emitting surface. This structure improves heat dissipation, reduces optical loss, and provides more uniform illumination, making it ideal for high-power LED electronic luminaires.

Technical characteristics:

- Luminous efficacy: 120-180 lm/W

- Uniform light emission, minimal shading.

- Low thermal resistance (RØ < 2° C/W typical)

- Suitable for high current operation.

Advantages:

- Excellent thermal conductivity for a long service life.

- High lumen density for compact luminaires.

- Reduced glare and improved optical control.

Disadvantages:

- Limited RGB customization

- Requires precise thermal management and driver control.

Applications:

- Street and tunnel lighting

- Reflectors and spotlights

- Industrial-grade electronic LED modules.

COB vs SMD: Technical Comparison for LED Electronic Systems

| Parameter | SMD LED chips | COB LED chips |

| Structures | Discrete LEDs on PCB | Multiple chips on the substrate |

| Light emission | Modern and high | Very high and uniform |

| Thermal conductivity | Average | Excellent |

| Beam angle | Wide (up to 160°) | Focused (60° – 120°) |

| RGB compatibility | Yes | Limited |

| Maintenance | Diodes that are easy to replace. | Module replacement required. |

| Power density | Moderate | High |

| Cost-benefit ratio | Minor | Slightly tall, but durable. |

| Typical use | Display strips, decorative lighting | Floodlights, high-height industrial lighting |

Electronic integration and circuit design

In modern LED electronic systems, LED chips are integrated with drivers, resistors, and thermal management components. Key design considerations include:

- Constant Current Drivers: They maintain a stable current to prevent overloading the chip.

- Printed Circuit Boards (PCBs): Circuit boards with a metal core improve heat dissipation in COB LEDs.

- Heat Sinks and Heating Pads: Essential for high-power setups.

- Optical Lenses: They control the beam shape and brightness uniformity.

The electrical and thermal balance of an LED circuit directly affects the chip's performance. For example, an SMD module operating at 60°C will have reduced light output compared to the same chip operating at 25°C.

Materials and Manufacturing

The efficiency of LED chips depends on the revision of epitaxial growth and encapsulation technologies. Common materials include:

- Substrate: Sapphire or Silicon Carbide (SiC)

- Epitaxy Method: Metal-Organic Chemical Vapor Deposition (MOCVD)

- Encapsulation: Silicone or epoxy for environmental protection.

- Phosphor CoatingConverts blue light into white light for general lighting applications.

Leading electronic LED manufacturers, such as Cree, Nichia, Osram, and Epistar, continue to refine chip structures to achieve higher lumens per watt output and improved thermal stability.

For use in LED displays and electronic panels.

In LED electronic panels, thousands of SMD or COB chips form the RGB pixels. Each pixel is composed of three subchips: red, green, and blue, which mix the light to produce millions of colors.

- SMD screens: They offer finer pixel spacing (as low as P 0.9) and wider viewing angles.

- COB screens: They offer better protection against dust, moisture and impacts, making them suitable for outdoor use and rental.

Leading manufacturers are now developing microchip COB LEDs, eliminating wire connections to increase durability and current distribution; ideal for microstep LED video walls used in control rooms and broadcast studios.

Future trends in the development of LED chips and electronic LEDs.

Advances in semiconductor processing are leading to new generations of chips. LED electronics, ...with greater energy efficiency and less miniaturization. Some trends include:

- Micro and mini-LEDs: Smaller diodes that offer superior resolution for fine-pitch displays.

- Quantum dot conversion layersThey increase color reproduction in LED screens.

- GaN-on-GaN substrate: It improves current management and efficiency.

- Intelligent electronic integration of LEDsCombining LEDs with IoT control for adaptable lighting systems.

Future trends in the development of LED chips and electronic LEDs.

Advances in semiconductor processing are leading to new generations of LED electronic chips with greater energy efficiency and less miniaturization. Some trends include:

- Micro and mini-LEDs: Smaller diodes that offer superior resolution for fine-pitch displays.

- Quantum dot conversion layersThey improve color reproduction on LED screens.

- GaN-on-GaN substrate: It improves current management and efficiency.

- Intelligent electronic integration of LEDsCombining LEDs with IoT control for adaptable lighting systems.

How to choose the right LED chips for your LED electronics project.

When choosing between COB and SMD for electronic use in LEDs, consider:

- Brightness requirements: COB for high intensity; SMD for flexible and color-rich designs.

- Thermal conditions: COB supports higher temperatures with enhanced thermal management.

- Screen resolution: SMD is suitable for finely spaced pixels and dynamic color control.

- Environment: COB offers greater protection for outdoor installations and in environments with high humidity.