Introduction

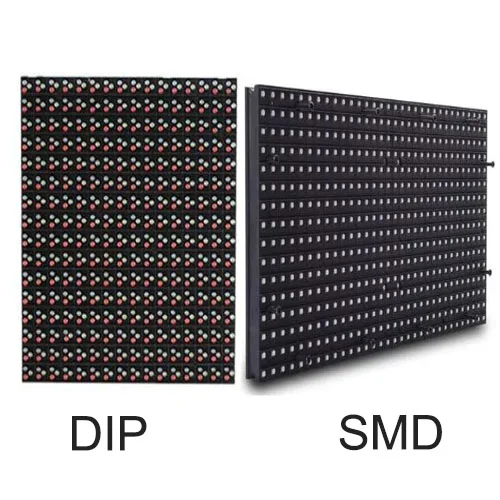

When selecting LED modules, you will likely encounter the terms LED DIP SMD. However, the choice isn't just about technical jargon; selecting the wrong type can compromise brightness, resolution, durability, and energy consumption.

Imagine installing a large outdoor panel and discovering that the image is blurry up close or, even worse, that the brightness can't compete with daylight. Or imagine an elegant videowall The indoor image is blurry because you used the wrong type of LED. These mistakes cost time and money.

In this article, we will clarify the differences between the technologies. LED DIP vs SMD. You will understand how each one works, their pros and cons, and exactly when to use one or the other so you can make a smart and economical decision.

What is a DIP LED?

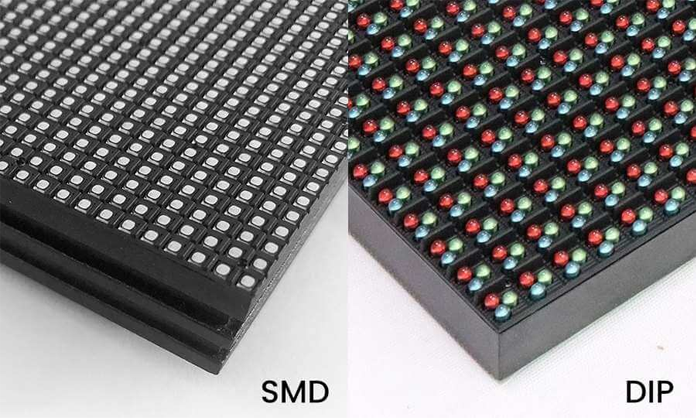

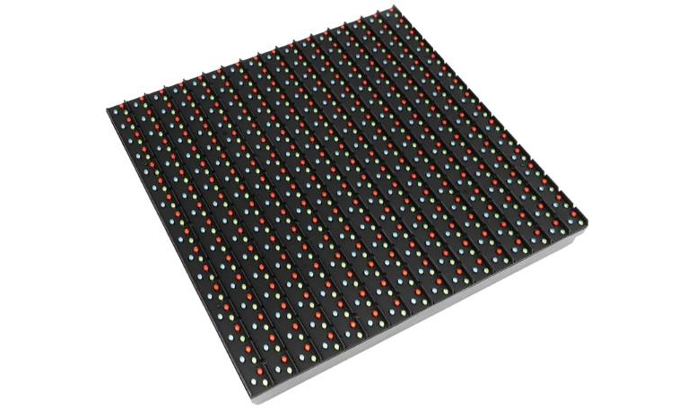

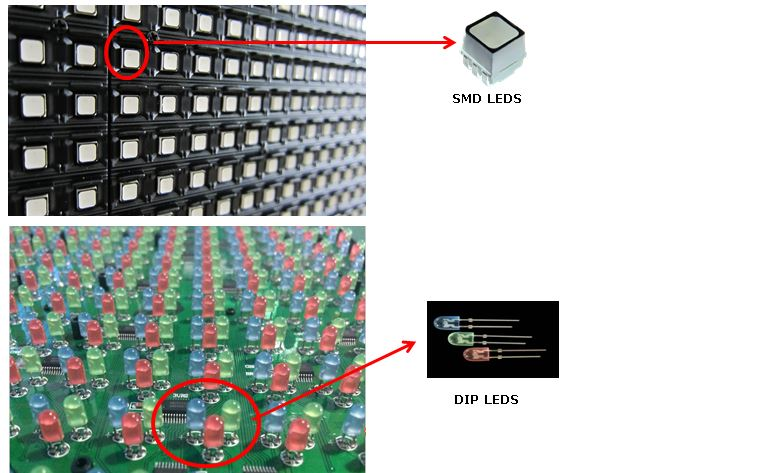

“DIP” stands for dual-in-line package. In this technology, individual LED chips (usually red, green, and blue) are housed in separate compartments, each with long pins that run across a printed circuit board.

Due to their through-hole mounting and larger component size, DIP LED modules are typically bulkier and heavier.

Main Features:

- Excellent shine and durability in outdoor conditions.

- A wider spacing between pixels (distance between LED chips) means it is more suitable for longer viewing distances.

- Highly robust, the thick packaging and the design with fastening pins provide great resistance to vibration and extreme weather conditions.

What is an SMD LED?

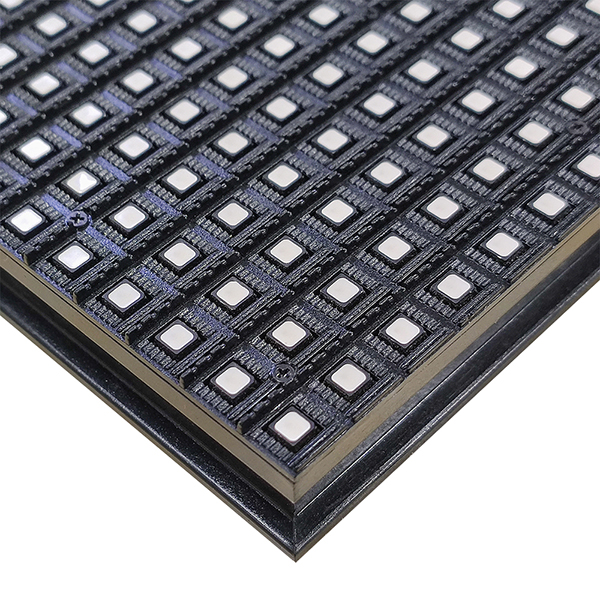

“"SMD" stands for surface mount device. In this case, the LED chips (usually red, green, and blue combined) are mounted directly onto the surface of the board, in compact packages.

This allows for denser compression (smaller pixel spacing), higher resolution, and wider viewing angles.

Main Features:

- Excellent image quality and color fusion, especially for indoor applications or close-up viewing.

- Lighter and thinner modules, ideal for modern screens with aesthetic or space constraints.

- It can be used outdoors, but in general, the brightness may be lower than that of a DIP lamp in full daylight, unless it is specifically designed for that purpose.

LED DIP vs SMD: Side-by-side comparison

| Appeal | LED DIP | SMD LED |

| Glow for outdoor daylight | Very tall, ideal for large outdoor spaces. | Okay, but it might be less intense than the extreme use of daylight by the DIP. |

| Viewing distance and pixel size | Larger pixel spacing, nest seen from afar. | Smaller pixel size, sharper details at shorter distances. |

| Viewing angle | Narrower viewing angle | Wider viewing angle, better peripheral vision performance. |

| Durability and resistance for outdoor use. | Very robust | Good, but it may require better thermal management in extreme conditions. |

| Energy efficiency / modern design | More basic design; sometimes less efficient. | In general, more modern and efficient packaging. |

| Best use case | Large outdoor signage, video screens in stadiums, billboards on highways. | Indoor video walls, retail displays, and locations where viewers are close together. |

How to decide which one to use

Step 1Consider the viewing distance.

If people are viewing your display from many meters away (for example, 20 m or more), a larger pixel pitch type, such as DIP LED, may be sufficient. On the other hand, if your audience is close (for example, 3-10 m), SMD LED, with its finer pixels, will provide better sharpness.

Step 2Consider the environment and the brightness.

For outdoor use in direct sunlight, DIP LEDs offer proven brightness and robustness. However, if your environment is indoors or shaded outdoors where high resolution is important, SMD LEDs will likely be the better choice.

Step 3Consider the budget and the life cycle.

DIP tends to be more economical for large applications with lower resolution requirements. SMD generally has a higher initial cost, but can provide better visual appeal and energy savings over time.

Step 4: Maintenance and technical assistance.

Due to their simpler construction, DIP LEDs can be easier to repair in harsh environments. SMD modules require more precision but allow for more discreet installations.

When the difference between LED DIP SMD is significant

- An urban billboard facing a highway: brightness for those at a distance is crucial – opt for LED DIP.

- The display wall of a retail store Viewed from a distance of 2 to 4 meters: details matter, viewers get closer – and SMD LED technology is the winner.

- For a mixed-use outdoor display with near and far viewing angles: you might consider a high-quality SMD outdoor display designed for high brightness (but the cost will be higher).

- Economical design for outdoor locations exposed to the elements: robust DIP coating can offer reliability at a lower cost.

Conclusion

In summary, when comparing DIP LEDs vs. SMD LEDs, there is no single answer. Each technology has its strengths: DIP LEDs excel in brightness and durability for long-distance outdoor viewing; SMD LEDs shine in high-resolution indoor installations and for short distances.

If you're planning your next display project, consider the viewing distance, the environment, and the budget. Then, choose the technology that best suits your use case.

If you would like expert guidance on how to choose or specify DIP or SMD LED modules, especially in relation to custom installations or displays, get in touch. We will help you find the ideal technology for your goals and achieve the right result.