Did you know that the price of your LED panel Is it determined by multiple components? Discover how each part influences the final value:

Main Components (60%-75% of total cost)

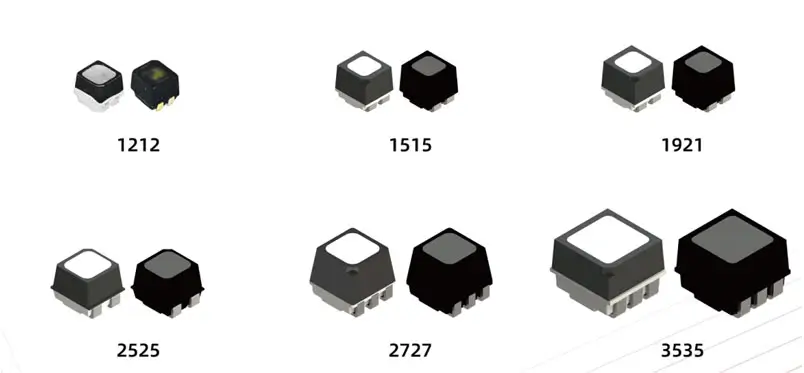

LED Lamps (30%-50% value)

Cost ratio: Generally the highest individual cost, which can reach 30% to 50% or even more of the total cost.

Influencing factors:

Pixel density (points step): The smaller the pitch (such as P0.9), the number of lamps required increases exponentially, the unit price is also higher (small lamps are difficult to manufacture), and the cost increases dramatically.

Lamp type and quality: SMD (Surface mount) is the most common process; COB (Packaging integrated into the chip), GOB (glue sealing) and other processes are more expensive, but offer better protection, +30% in cost.

Shine: High-brightness lamps (especially for outdoor use) are more expensive.

Wavelength consistency (Bin value): Lamps with a high Bin value (highly consistent color) are filtered more harshly and cost more.

Packaging materials and processes: affect heat dissipation, waterproofing and UV protection capabilities.

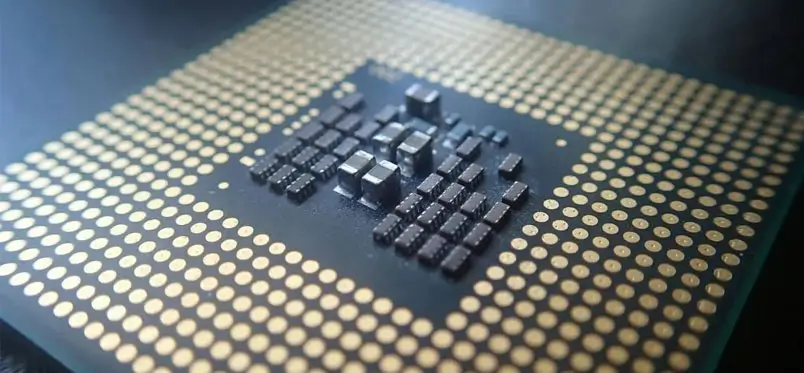

Driver IC and PCB (Printed Circuit Board)

Total Cost: 15%-25% of your LED panel value

Factors that Impact Price:

Driver IC (Integrated Circuit):

Premium brands like Texas Instruments or MBI increase the cost, but guarantee:

• High refresh rate (up to 3840Hz → ideal for gaming and videos)

• More gray levels (16bit+ for realistic colors)

Technology: Constant current drivers are essential to avoid flickering

PCB (Circuit Board):

Layers:

• Small pitch (e.g. P1.2) requires 4-6 layer HDI boards (+30% cost vs duplex boards)

• Materials: High TG (thermal resistance) and gold plating (reliability)

Components: High-quality resistors and capacitors prevent premature failure

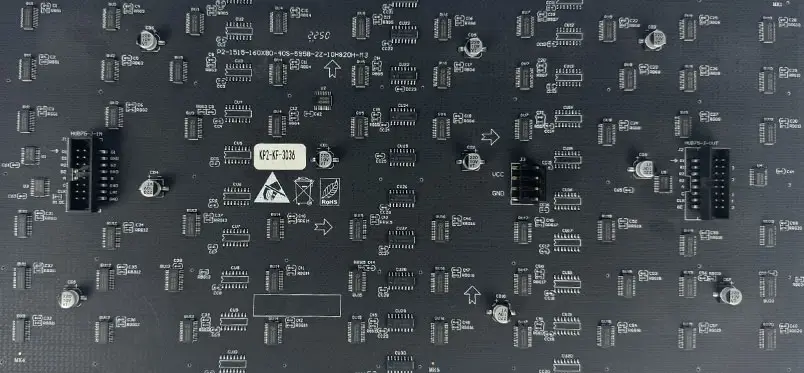

Display Modules/Unit Boards

What are they?

Modules are the basic units of your LED panel, where:

- LED lamps are soldered onto PCBs

- Drive circuits (drivers) are integrated

The value reflects the sum of:

Cost of LED lamps (30%-50% of total)

PCB cost with drivers (15%-25%)

Additional processes:

• SMT assembly (automatic soldering technology)

• Rigorous quality testing

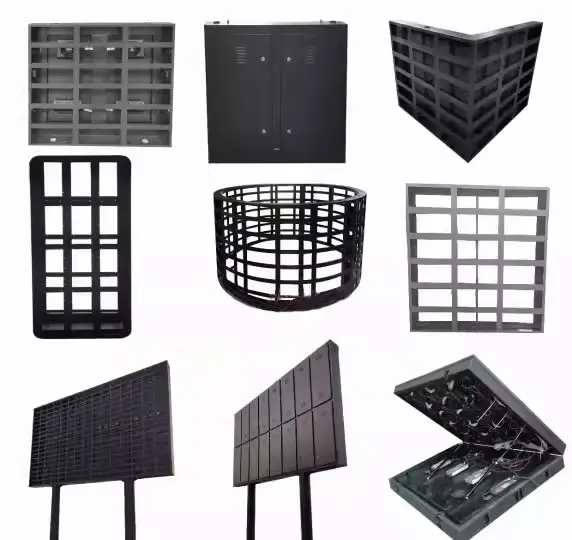

Structure/Cabinet (10%-25% of total cost)

Top 3 most used materials in Brazil

Injected aluminum:

- King of LED courts (65% of premium projects)

- Advantages: +30% resistance vs metal sheets, dissipates heat 2x better

- Price: R$150-300/m² (50% more expensive than steel cabinets)

Carbon fiber:

- For special events (tours, Grammys)

- Weight: 3.5kg/m² (70% lighter than aluminum)

Reinforced plastic:

- Economical for indoor (shopping malls, churches)

- Cost: 60% less than metal

5 factors that make your cabinet more expensive:

- IP65+ (mandatory for outdoors) → +15% cost

- Magnetic closure (quick maintenance) → +R$80/unit

- Ultra-thin design (<80mm) → Requires special alloys

- Integrated cooling system → Requires internal channels

- Anti-impact corners → Protect during transportation

Most popular installation types:

- Quick-lock rail (10s per module) → Ideal for rentals

- Invisible suspension → For architectural facades

- Folding base → Corporate events

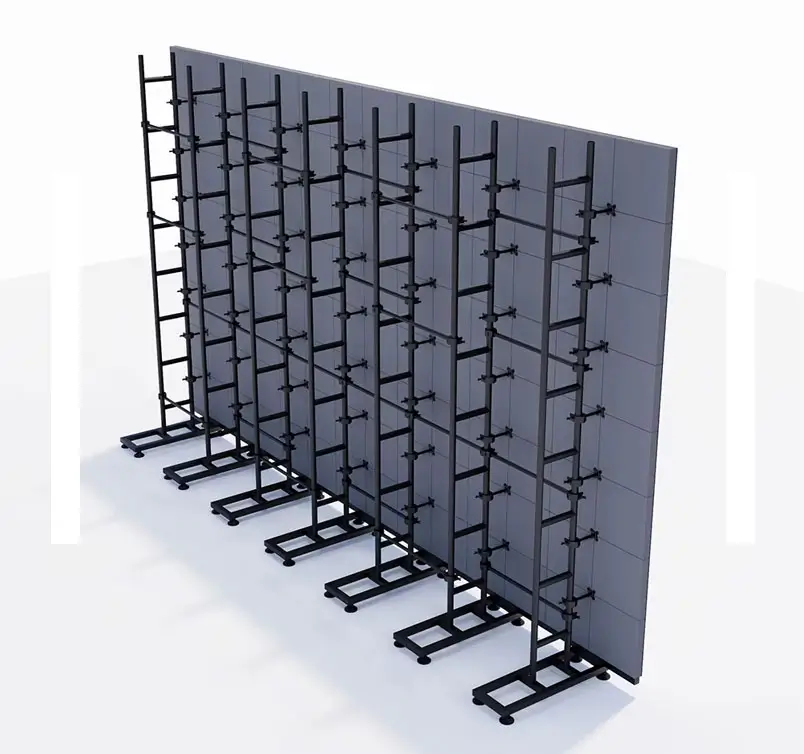

Module/unit board installation structure

magnetic attraction, locking screws, etc.

Power Supply Cost (5%-10% of total)

Factors that Determine the Quantity of Sources

- Total panel area → Example: 10m² panel needs 2x more fonts than one of 5m²

- Brightness (nit) → Panels above 5000cd/m² require more powerful 30% sources

- LED consumption → High-efficiency models (2W/LED) reduce the amount needed

Premium Brands vs. Generics

| Comparative | Top Brands (MW/MeanWell) | Generic Brands |

| Efficiency | >92% (Save up to R$1,800/year on 100m²) | <85% |

| Protections | 5 layers (against surges, short, overvoltage) | Basic |

| Useful Life | 80,000 hours (10+ years) | ~30,000 hours |

| Relative Cost | 0.4 | 100% base |

Golden Tip:

80Plus Gold certified sources save 15% on your electricity bill vs. conventional models

Redundant Configuration (N+1)

- Where to use: Live events, hospitals, airports

- Additional Cost: +12-18% per extra source

- Advantage: Avoids catastrophic failures (99.99% uptime)

Practical Example (São Paulo):

Outdoor panel P10 20m²:

8 MW 60A sources (R$420/pc.)

+1 redundant → Total: R$3,780

Estimated savings: R$620/year in energy vs generic

Control system cost (about 5% to 15%)

Emitting plate

Responsible for receiving signals from the video source, processing them, and distributing them to the receiving cards. Performance (supported resolution, load capacity, refresh rate, grayscale, HDR, multi-screen processing, type/number of interfaces) and brand (such as Nova, Linsn, Colorlight, LEDOK, Moseer, Kystar, etc.) are the main cost factors. High-end sending cards are expensive.

Receiving board

It receives instructions from the issuing board and triggers the module's display in the corresponding area. The number is determined by the screen's pixel size. Performance and brand also affect the unit price.

Video processor (optional, but common in complex applications):

Used for multi-source switching, scaling, splicing, special effects processing, etc., with large price differences depending on the complexity of the function.

Cables

Network cable (CAT5e/6 for sending card to receiving card), optical fiber (long-distance transmission), power cable, etc. High-quality cables and reasonable wiring design are more expensive.

Cooling system cost (especially for outdoor/high brightness displays, variable)

Natural cooling

Depending on the design of the cooling teeth in the box, the cost is the lowest.

Forced air cooling

Add a fan (the cost is not high, but the fan itself and maintenance need to be considered).

Air conditioning/constant temperature system

Used in extreme environments or ultra-high-density, high-brightness displays, the cost is very high, including the air conditioning equipment itself, installation, additional energy consumption, and maintenance.

Support and installation project costs (variable, can represent from 10% to 30% or even more)

Steel frame/structure

The structure that supports the entire screen. The larger the scale, the higher the installation location (such as a roof), the greater the load-bearing requirements, and the more complex the structure (such as an arch or spherical), the higher the cost. Materials (steel frame, aluminum frame), design, and construction complexity are crucial.

Installation costs

labor costs, lifting costs, high-altitude operating costs, construction time, etc. The cost of complex installations (such as special-shaped screens and high-altitude operations) has increased dramatically.

Power distribution system

cables, distribution boxes, air switches and possible costs of expanding power capacity.

Protection system (external)

lightning protection and grounding system.

Monitoring/Operation and Maintenance System (Optional):

remote monitoring, temperature and humidity sensors, light sensors, etc.

Content production/broadcast control system (optional):

playback software, servers, etc.

Other costs

Packaging and transportation

Especially for large screens and export projects, packaging and logistics costs are considerable.

Taxes

Value Added Tax, etc.

Manufacturer's profit

Different brands, scales and service levels have different profit margins.

R&D and design fees

Custom projects or new product development will share this part.

After-sales service and warranty

A longer warranty period or a more comprehensive service commitment will be implied into the price.

Main variables affecting total cost

Distance between points

The most important influencing factor. The smaller the dot pitch, the more delicate the display effect, and the cost also increases exponentially. For example, the price of a P1.2 dot pitch screen can reach tens of thousands of yuan per square meter, while a P10 outdoor screen can cost only 1,000 yuan per square meter.

Screen size and resolution

The area determines the total amount of materials, and the resolution (total number of pixels) determines the number of lamp beads and driver integrated circuits.

Application environment

Indoor vs. outdoor: Outdoor displays require higher brightness, waterproof and dustproof rating (IP65+), more robust enclosures, heat dissipation/constant temperature systems and protection systems, and the cost is much higher than indoor displays with the same dot pitch.

Fixed installation vs. rental: Rental screens prioritize lightness, quick installation and disassembly, and durability, and the cost of the cabinet structure represents a higher proportion.

Brightness requirements

High brightness requires high quality/power lamps and power supplies, which increases heat dissipation requirements.

Refresh rate and grayscale level

High refresh rates (such as ≥3840Hz) and deep gray (such as 16-bit+) require more advanced driver ICs and control systems.

Product format

Conventional flat screen vs. curved screen, spherical screen, floor screen, transparent screen, Creative screens with special shapes, etc., special shapes increase design and manufacturing costs.

Brand and quality

Component Brand: Using top-tier brands for key components such as lamps, ICs, power supply, control system, etc. significantly increases the cost.

Screen manufacturer's brand: The investment of renowned brands in R&D, quality control, technology and service will be reflected in the price.

Degree of customization

Standard products vs. custom products with special sizes, shapes, and functions (such as interaction).

Project scale

Large-scale acquisition often offers discounts, but the cost of supporting projects also increases proportionally.

Installation difficulty and environment

High altitudes, complex building structures, and special locations (such as hospitals and explosion-proof areas) increase installation costs and engineering complexity.

Summary

The cost of an LED display is a comprehensive reflection of the cost of the display's main components (lamps + driver PCB), structural housing, power supply, control system, supporting engineering and installation, etc. Among these, pitch (pixel density) is the most important technical parameter that affects cost, directly determining the number and cost of lamps and driver PCBs. At the same time, the application environment (indoor/outdoor) and performance indicator requirements (brightness, refresh rate, grayscale) also significantly affect the final cost. When evaluating the price, a detailed analysis should be performed in conjunction with the specific project requirements and technical specifications.